- Home

- About Us

- Join/Renew

- Member Benefits

- Member Pages

- Log In

- Help

- Museum Store

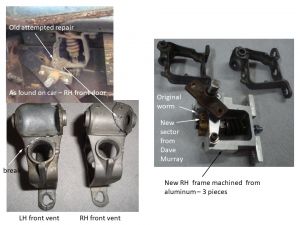

Both of the castings that hold the worm and sector gears to turn the front vent windows were broken on my 845 Club sedan. I started to look for replacements but figured they are a weak link, and any I found would probably be overstressed and fail anyway. I have a third casting from another car broken in the same way. So, I decided to make new beefier ones by machining from aluminum.

The first problem is that they appeared to be handed LH/RH and there is a very subtle 3d angle to the axis of the worm meshing with the sector that is under 2 degrees from perpendicular. Next, both casting had some twist, and one is twisted more than the other. The casting for my rear door vents are not broken but are also twisted, with one being barely twisted and the other significantly more.

I took the measurements for my replacements from the front LH that was broken but had little twist, assuming it was the closest to original. There is a number 70302 (not a 6 digit P-A part number) on the casting that can only be seen after removing the worm. After removing the worm from the RH I was surprised to see the same number as the LH, implying they originally were the same casting and not LH/RH. The subtle angles maybe weren’t there originally either. In other words, they only became different after they were overstressed cranking the windows in and out. In the P-A parts book page 206 the vent window “operator groups†for front LH/RH, and different rear LH/RH are listed with different numbers. Unfortunately the P-A parts book does not break down to the detail parts level to list the castings. Perhaps the assembly “operator group†numbers are only different because they had different LH vs RH worm and sector meshes and different crank shaft details? Does anyone have any knowledge on this?

I have already made the “handed†replacements for my car that I think will be mission adequate. They are 3 pieces screwed together. The question of interchangeability may be relevant if others out there need replacements for these. I have designed my replacements so they could be CNC machined and I obtained an initial estimate from 3Dhubs of about $350 for a single, but this price drops to ½ or 1/3 with short runs of 5 or 10. The price would drop further if one design fits all.

Jim

If you have these made I’m sure there are a few people that would pick them up from you.

It’s not doubt that pretty much all of the same vintage cars are suffering the same fate as yours.

Well done! Reproductions were made years ago, and haven’t been available for ages. Always much more to these projects than people realize.

Rich Anderson of WA made excellent repros of these about 10 yrs ago. The prices were very reasonable.

Richard responded to my question on RH and LH and his recollection is that he reproduced only one casting design – not handed. I have since remade my machined parts to take out all the wonky angles so they would not be handed at all and did a fit check, they seem to be better. All the wonky angles seem to have been from twisting from being overstressed and not the original design. It appears that a single design is used for all front LH/RH and rear LH/RH. This simplifies the design and increases the production runs and reduces the costs. I have done a redesign of the part so it could be done as a single one piece aluminum CNC machining. It would not look like the original but should be significantly stronger.

I don’t know what years beyond ’34-’35 this piece would cover and what the demand might be.

Jim

I originally assumed that the castings twisting and breaking was simply due to windows being overstressed from tight or sticking fits into the weatherstripping rubber. However, in checking the fit-up of the new machined parts versus the original castings I found that they were originally assembled with a significant interference when attached to the large plate that holds the window regulators and door latches. This was forcing a significant load on the casting that was probably a big contributor to their failure. When re-installing the castings it may be necessary to open up the hole in the plate the bronze bushing goes through and redrill the attaching holes so that there is no load on the shaft and bushing when the plate is assembled. See the attached pictures.