- Home

- About Us

- Join/Renew

- Member Benefits

- Member Pages

- Log In

- Help

- Museum Store

Home Page › Forums › What did you do with your P-A today? › Top nail strips – 2nd round

Tagged: top nail strip

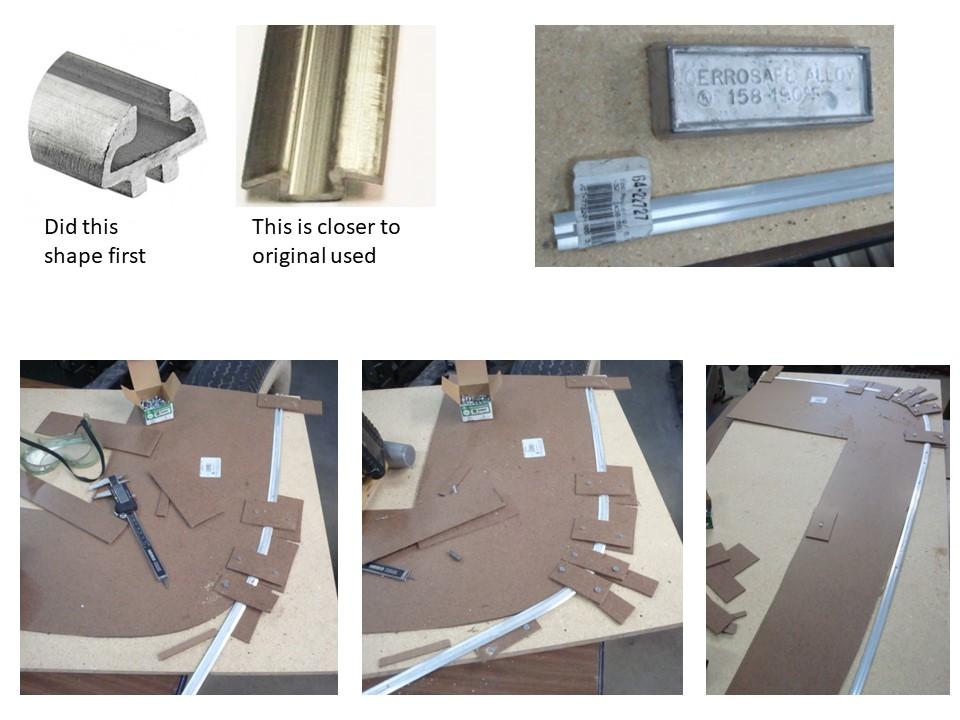

I bent a set of nail strips for my top insert many months ago using a Ford extrusion that looked like it could be bent to the curves with less problem with its inward flanges and would seal better. However after the fact realized that it would take excessive force to pound the flanges down after installing and stand a lot taller than the originals. The Ford upside down hat section that is close to the original used on the ’35 Pierce seemed like a nightmare to bend to the curves with the unsupported legs. However, after trading some emails with members who had done it I decided it was worth a try. First is using a low temp casting alloy to fill the trough to keep the inside channel from collapsing the f while bending. I used a thin hardboard to form the bend against while supporting the flanges with straps to keep the shape from twisting while bending. A bit surprising, but it worked well enough with this rudimentary tooling. 1 down, 3 to go.

the f while bending. I used a thin hardboard to form the bend against while supporting the flanges with straps to keep the shape from twisting while bending. A bit surprising, but it worked well enough with this rudimentary tooling. 1 down, 3 to go.

Looks like it’s working well…where did you buy the strip? I assume you can buy the low temp metal from McMaster Carr…thanks David Coco Winchester Va.

Yes, cerrosafe alloy block from McMaster. Pretty strange working with a bright metal that melts below 200. Keep thinking I’ll get scalded.

Extrusion is from Mac’s, same one is available from Snyder’s. Look out for shipping charges, can be more expensive than the pieces and gets tacked on per piece.