- Home

- About Us

- Join/Renew

- Member Benefits

- Member Pages

- Log In

- Help

- Museum Store

Home Page › Forums › What did you do with your P-A today? › Spring shackle pin removal

Tagged: Oil of Wintergreen, Thread Penetrent

Happy New Year everyone.

I thought I would start the year tackling the shackle bolts. I had viewed this with some fear and trepidation.

First I had to remove the pin retaining screws. Heated the screw then the boss with my hot wrench. I heated the boss until the rust burned off then melted a piece of candle wax on the screw and they turned right out. Maybe 2021 isn’t going to be so bad.

While the boss was still hot, I melted more wax in the screw hole and on the outside of both ends of the shackle pins.

I used a 4″ sledge to drive the pin towards the center of the car until it was flush with the boss.

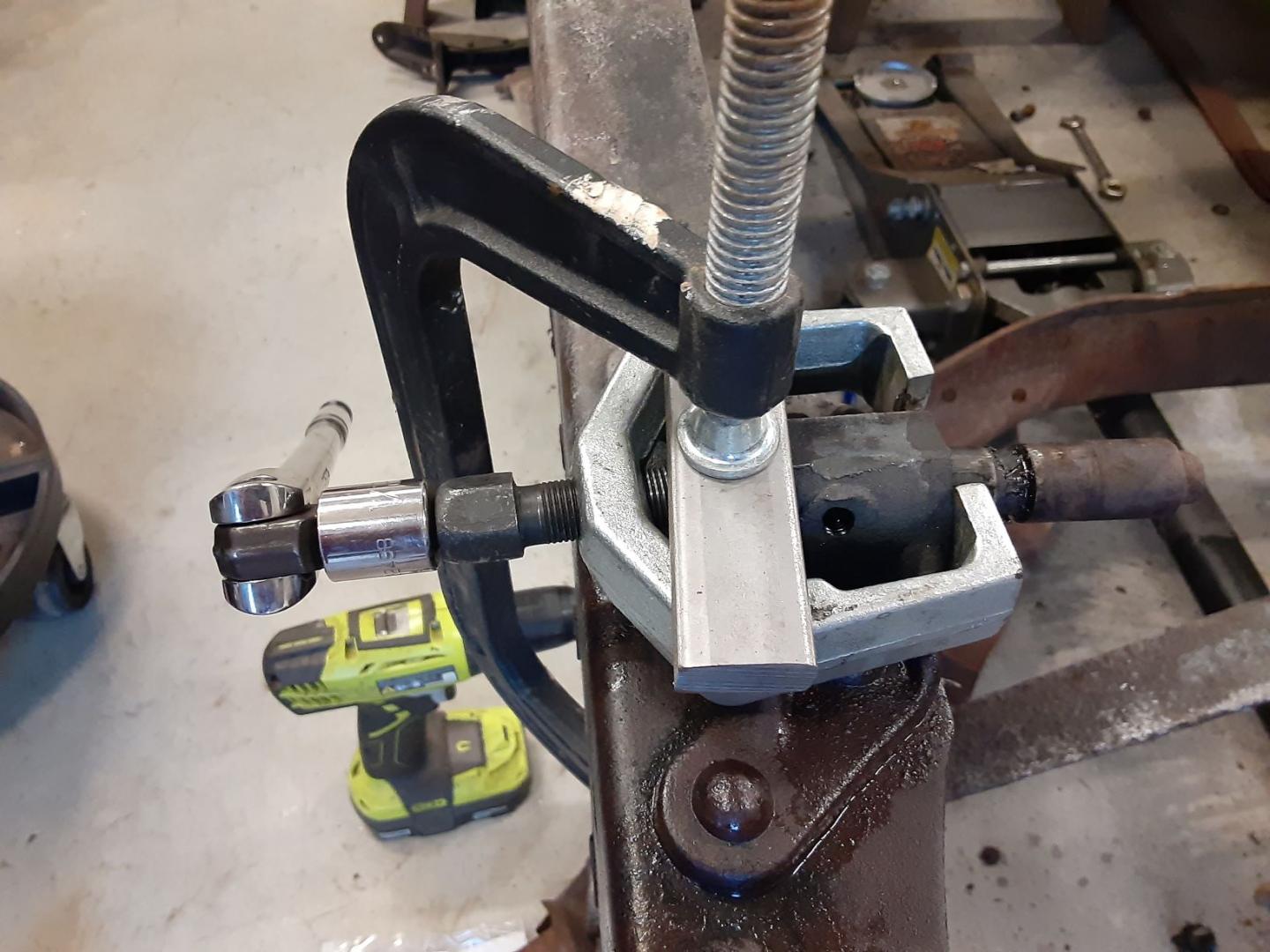

To push the pin the rest of the way out, I used a tie rod end removal tool. I had trouble keeping the press bolt centered on the head of the shackle. It wanted to walk off the head so I put a retaining bar on top of the press and held it in place with a large “C” clamp on the frame.

Pin pushed right out, but it was very tight.

One day does not a year make, but at least it started off in the right direction.

I finished removing all the set screws and pins.

The set screws required at least one of the following techniques

From left to right. The offending set screw. All but one of the set screws in the springs came out with just a screwdriver, some in the frame required a SPEEDOUT which is basically a reverse rotation bit which helps center the bit in the screw, next was a left hand bit and finally a “F” drill bit for 5/16-18 tap. If the screw driver didn’t work, I center drilled the screw with the SPEEDOUT. If the other end of the bit that grabs the hole didn’t work, then I used a left had drill bit. If all else failed I just drilled out the hole with the “F” bit and retapped. I ended up retapping 3 holes

The pins were able to be pressed out except for the rear most ones and they required the use of a BFH.

Bill,

For these really difficult to separate parts, try Oil of Wintergreen as a solvent to wick through the rust and loosen things up a bit and reduce the size of BFH required.

Back in the day, when I was a young engineer at the power plant, we used this oil as the penetrant to loosen the large nuts and bolts holding the both steam turbine shell halves together, at the 5 year rebuild cycle. This oil loosened the threads enough, so they could be removed with only slugging wrench and small sledge hammer. In the years before using this solvent, they broke off several of these 1-1/2″ bolts with just brute force. The older mechanics swore that oil of wintergreen was the very best penetrant to use, as it would get into places the other fluids wouldn’t touch. Herb

Herb,

Well I have some of that in stock as it is used to soften rubber. I will have to give it a try.

Did you figure out our car noise?

Thanks for driving.

Bill