- Home

- About Us

- Join/Renew

- Member Benefits

- Member Pages

- Log In

- Help

- Museum Store

I have been following the side-mount tire discussion and another discussion on the AACA forum and rather than highjack the discussions, I decided to start a new one. I am getting confused about wheel terminology. I have heard the term “split rim†and “lock ringâ€. They are frequently used interchangeable but from what I can gather they are not the same thing. Also, I was recently talking to a person at Universal tire about getting new tires (they are located close to me). I told him I have split rims. He said he could mount new tires for me, but could not inflate them if they were lock ring rims. I told him I do not have lock rings. He then said he could mount them and inflate them if they were simply split rims. As I look at my wheels (wooden) the rims are split (e.g. the rim is not connected all the way around, but has a “break†where the rim can be separated. However, there is no locking ring to hold the tire on the rim. The rim has shoulders that hold the tire and the tube within. I do not see where this type of rim is dangerous or can cause harm. I presume the tires can be mounted with the use of a split rim tool. Alternatively, I have seen photos of “locking rings†that are needed to hold the tire on the rim. It is my understanding that these latter locking ring rims are the dangerous ones. If the locking ring lets loose it can fly off causing serious damage. So are my definitions correct?

Robert

Robert’

You are correct. Split rims mean there is one part of the metal rim that literally splits open so the tire can slide over the reduced circumference. Once one side is in place, you feed the tube into the inside of the tire, then slide the other side of the tire over the rim. Then you return the split rim back to its original circumference.

The lock ring type tires were common on trucks back in the 70’s. I can remember changing these tires, and when inflating them, we left the shop until we heard a pronounced POP, then we went back and filled the tire to the proper pressure. I have seen one of these rings take off and embed itself in the ceiling. Not a pretty sight. I worked for a roofing company. Most real shops had a cage used to protect mechanics when replacing tires. Not us.

Universal should have no trouble handling your tires.

Hi Robert. This is obviously for your ’29 Roadster. I think you should mount at least one of these tires yourself, it’s a great way to understand the dynamics of the mounted tire and tube.

Plus, it builds ‘character’. Hmm maybe that’s why I’m such ‘a character’ ?? I’ve always changed my own tires on my antique cars. I even changed them on my Kenworth T-300 Semi. Why because I never know when that bit of knowledge and experience might be what I need to get my truck, or a friend’s truck back on the road.

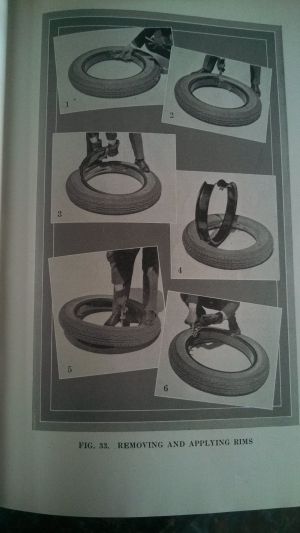

Here is a photo of the tire-changing instruction page from a S.80 owners manual. Hopefully it will help explain the process.

Greg Long

Dear Bob and Greg, thank you for the replies.

Greg, I agree with you completely. Now that I am sure my wheels will try and kill me, I am happy to change my own tires. I want to purchase a split rim tool and do them myself. It was simply the conversation with the person who worked at Universal and the interchangeable use of the terms that got me wondering about the differences. Also, thanks for the tire changing photo page! I will definitely print it and use it.

Robert

Robert,

Take it from me, you do not want to try and change a tire on a rim on a Pierce-Arrow while wearing a suit, as pictured above (Chauffeur?).

I believe that Arnold Romberg / Dave White published in a recent PASB my process of how to change the tube and tire on a Series 80 split-rim.

It definitely has a learning curve and you have to be careful, because the rim can bite you if the split rim tool jumps off of the rim.

You do need a GOOD tri-legged split rim tool and a number of tire irons.

You also need Tire Lube and Tire Talc.

If you want details not found in the PASB, be in touch.

Peter

Peter,

Thank you for information and advice. I will be in touch when the time to change tires (sans suit) occurs.

Robert

You should mount your own tires, as Greg implied, if only to understand the process and determine that you can or cannot do it yourself. It does take muscle but it is educational.

When mounting any tire I’ve found the use of a lubricant to be absolutely essential. And I’ve done many tires. Dish detergent, talc, WD-40. . . all this stuff is not good enough and some of it unwise. What I’ve found best is the dedicated tire lube paste found in most parts stores. I am not endorsing a particular product but what I’ve used is this “Europaste” stuff, shown in the photo. Used liberally it makes any mounting job much easier. I’ve tried, in my younger stupider years to not use a lubricant or only talcum powder to no avail because rubber wants to stuck to metal. You need to make the rubber slide over the metal.

The other advice is to use your tire irons to take small little “mouse bites” to work the tire on, little at a time. Never try to horse the whole thing or a large section on all at once.

Same with a split rim. Getting the tire over the slit rim may not be too hard, but closing the split rim can be nearly impossible without generous tire lube.

Again, experience is the best teacher.

— Luke

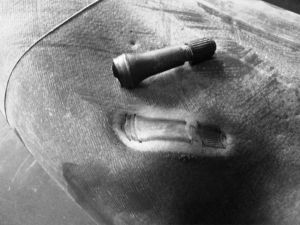

And since the software won’t allow me to post more than one photo. . .

The other reason to do it yourself is shown in this second photo. Often you simply can’t trust the shop doing it for you. The photo shows why I had a slow leak in a Packard tire for nearly a whole season after I hired a shop to mount my lock-rim tires. Some monkey with a double digit IQ actually left a sliced off valve stem inside the tire. The abrasion between the tube and the valve stem caused a slow leak. Eventually I took the tire off and discovered the problem. As the cliche goes “It’s so hard to get good help these days””.

–Luke”

And since the software won’t allow me to post more than one photo at a time. . . .

I’ve done many lock ring tires myself. It’s not hard. Actually it’s pretty easy — much easier than split rims. You just want to make damned sure that while you inflate the tire that the lock ring is firmly seated, and you want to secure the ring with straps, rope, old leather belts. . . whatever so that it if does fly off, it will be caught. Never look down at the tire when inflating. Stay well clear. Secure a tire chuck to the valve stem, and turn on the air from a distance. I inflate in increments. Checking and double checking.

But as others have implied, if you are apprehensive at all about doing it, just have someone else. If a lock ring flies off, if can kill you really bad.

— Luke

Interesting discussion. I have a 1965 International Travelall (bought it in 1973)that came with lock ring wheels. For years the tire stores did not complain a bit. In the late ’90s I bought new wheels in order to change to radial tires, and now the tire men are absolutely aghast when I tell them that the original wheels were lock ring.

Joe Morgan

Luke, the set up you have is NOT sage when using snap rings……….the amount of stored energy in the tire will blow past the belts like rubber bands. I don’t even use a cage……….I have a 100 foot Lon air hose with a locking air chuck on the end. I attatch it to the valve stem, and open the air valve on my compressor line slowly, until the tire comes up to pressure. I do this in the bright sunlight, to keep the tire soft and flexible. After the tire and ring hold 45 pounds for an hour or two, I bleed the air down to 25 pounds, inspect the ring at a distance, then get closer one it appears safe. I have seen two snap rings file……..and rest assured, each day as the rings get older, rechromed, and removed and installed mutiple times, they are not getting safer. Here is a NEW rim, new snap ring, and new tire all made by one of the best companies……and with 100 miles……..failure.

Sorry, I can’t fix the typos. From my phone….buttons are too small and the screen is too small to see what I am typing.

Ed,

Actually, your fingers are likely too big and your eyesight is in the over 40-years-old mode.

Get some reading glasses and keep them everywhere around the house and in the cars.

HA!

Peter

So you are hinting that Ed may be “over-the-hill””? It happens to the best of us……

Al”