- Home

- About Us

- Join/Renew

- Member Benefits

- Member Pages

- Log In

- Help

- Museum Store

Tagged: hand brake, Lever Sector, Parking brake, ratchet

Can anyone provide a drawing or pictures with measurements of the parking brake lever ratchet (the portion with multiple teeth)? Or even better does anyone have one we could purchase or use to replicate? Our 1929 is missing this part and we suspect we will have to machine a new one.

Joe,

Joe,

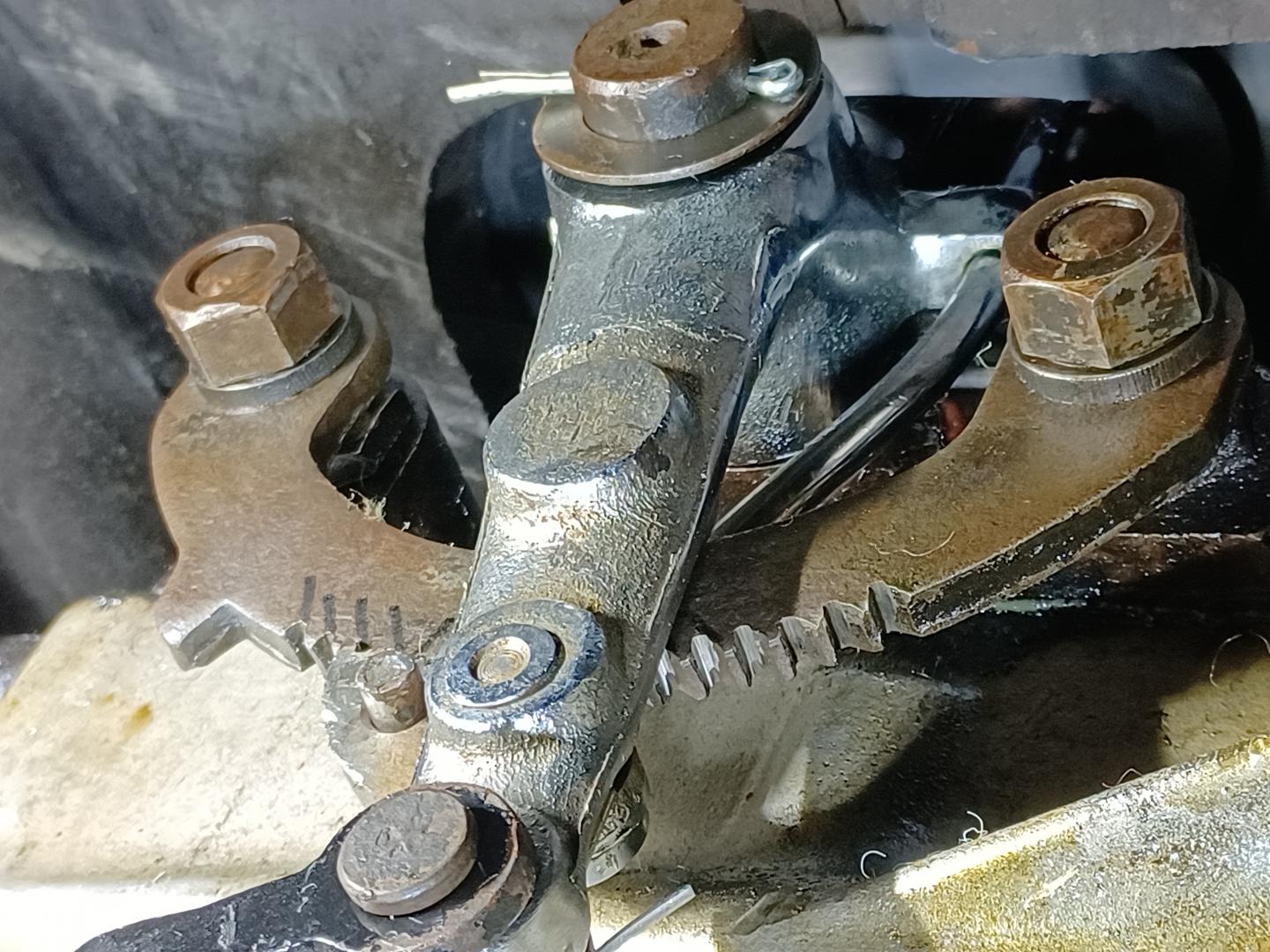

Here is a picture if the parking brake sector that you seem to be missing. Here are some important notes: (1) The OUTSIDE radius with the teeth requires a circular radius to allow the pawl to rotate around the teeth properly, but the inside radius is support only and radius does not matter. (2) the teeth are NOT a standard gear form, but have a straight side so the pawl will not slide out and release the brake unintentionally (I found that surprise when I purchased my Pierce). (3) Find a original, as this part is a stamping and be difficult to machine – call Cislak. (4 ) Paint is probably optional as there is enough leaking oil to prevent rust. I have more pictures to email if you are interested. Herb

This may be a good candidate for laser cutting or water jet. The laser jet company I use can cut up to 1/4 thick chrome moly steel and is very cost effective – generally much less expensive for single or short runs than machining if the part is a simple flat. The trick is creating a CAD file of the part to upload, which would need an original part or at least enough of an original piece to get the critical outer radius, teeth dimensions and attach hole location. It looks like a fairly simple part to design if an original is available.

Thanks Herb, I would be interested in the additional photos. We laugh that we have environmentally GREEN cars. They put oil back in the ground every time we drive them.

Thanks to you too Jim. That may be a good option if we can get a good pattern.

Joe,

The laser or water jet sounds like a very good fabrication method for this part. I don’t mind offering my sector for a limited time, but I was still hoping to get my car back on the road this fall.

(1) Do you anyone how can do the CAD drawing?

(2) How long would it take to copy mine before returning it?

(3) Can you please make several copies once the setup if finished? I would like a new replacement, and I suspect others would too. As our cars are mostly more than 90 years old and this is a (slow) wearing part, after this long, it will wear enough to be a bit unreliable and perhaps allow the car to sneak away. Herb.

Herb, I can do the CAD design. 2 options. You can send me the part and I can turn it around back to you in a week. Option 2, if you have a printer scanner you can scan the flat image and send it as a JPEG. I would need some very accurate dimensions to scale the image in my CAD program, preferably the maximum overall length edge to edge, mount hole diameters, and of course thickness. Cheap printer scanners are amazingly accurate if you can get the scale nailed down. After sending the image I might ask for a couple other dimensions to verify. This looks like a pretty simple part to recreate the design.

If Jim can get a drawing of Herb’s using one of the methods described it would be great. It may be good to do new pawl as well. We were going to build up ours with a weld and file it to match. Getting both matched may be better especially if other people may want them. We also have a local laser shop we have used if another production option is needed.

Thank you for your responses.

Do we know what other years, series, models this fits? I don’t want to get too ahead of ourselves but would be useful to know if there is a wider need for this.

I thought someone asked if we could get picture of the Pawl, though I can’t see that request now. As you can see in the picture we started to build up the old one with a weld. The second one we picked up on eBay (not specific to our car). It is different, but we thought we could modify it if our welded original did not work. I can scan these if it would help.

I will attempt to cross reference the parts to see if additional years and models use the same one. Herb’s picture does match ours.

The 1929 Pierce Arrow Parts Catalog proves its worth again. Page 18 shows the transmission and the view of the top shows the handbrake mount. The sector is noted as Part Number 123037, and is confirmed in the numerical parts list section. Joe’s reproductions are expected to fit models using this same part number. What hand brake sector are other models in this era using?

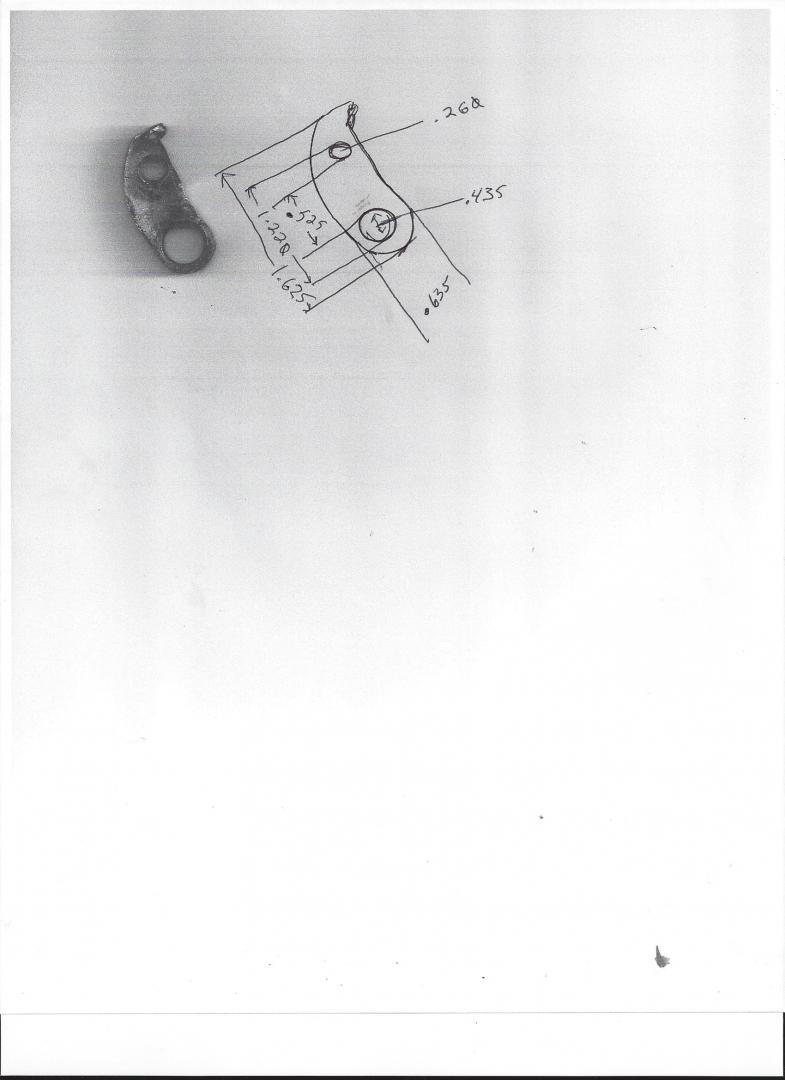

Joe, the picture of the pawl posted may be good enough to get an initial CAD design if you can give me a good dimension by calipers for the maximum overall length of the piece and the thickness to get a quick feasibility check for laser cutting.

Before actually getting anything made it will need to be removed and do a careful dimensional check – hole center to centers and diameters. I think I can match the pawl tooth geometry to match the sector Herb is sending.

I am going to grind the rivet tonight. I will scan the pawl after I get it off and then put some measurements on it. If that doesn’t work well enough we would be glad to send it to you.

Good. I don’t know what else these might fit but I can confirm unsurprisingly that the sector does not fit ’35.

Here is the scan with the measurements

Thanks to Jim for his work on the drawings we have ordered a few sectors and pawls. When we get them in we will install one and let you know how it works out. Herb, we would be glad to send you a set for your assistance in this project as well. We will update you after they arrive. Let us know if you want one.

Thanks again for all the assistance. We are very close to getting this lady back on the road again.

Joe,

Yes, I do want one of the new sectors you are having made. When I purchased my Pierce, the hand brake did not hold at all, so I had to remove the sector and file to the teeth enough to make them at least functional; it works for now, but I do not trust it for long term use. The pawl appears to be in good shape, so I am reluctant to cut the rivet to replace it. Having a new sector with consistent teeth, rather than my amateur “dentistry” will be a very welcome improvement for a car that will be driven. Herb

Jim,

Does anyone know if the ratchet you are reproducing will fit a 1930 model? It looks the same as the one on my Clark four speed on my model B, which will is also worn and will unexpectedly release and an inconvenient time. If so, I would be interested in purchasing one if available. Thanks for your efforts with this project.

Tom Barrett

Herbert, I will send you the sector, pawl, and a stainless steel rivet cut to the new dimension of the pawl. I believe Jim said he modified the teeth angle to match the pawl.

It really is simple to punch the old rivet out and put the new one in. I will verify the fit using my brake handle before sending them to you.

I have not heard yet when they will be produced and shipped. I will keep you informed. I have already machined the rivets.

Regards

Joe