- Home

- About Us

- Join/Renew

- Member Benefits

- Member Pages

- Log In

- Help

- Museum Store

Tagged: vent window bracket twist

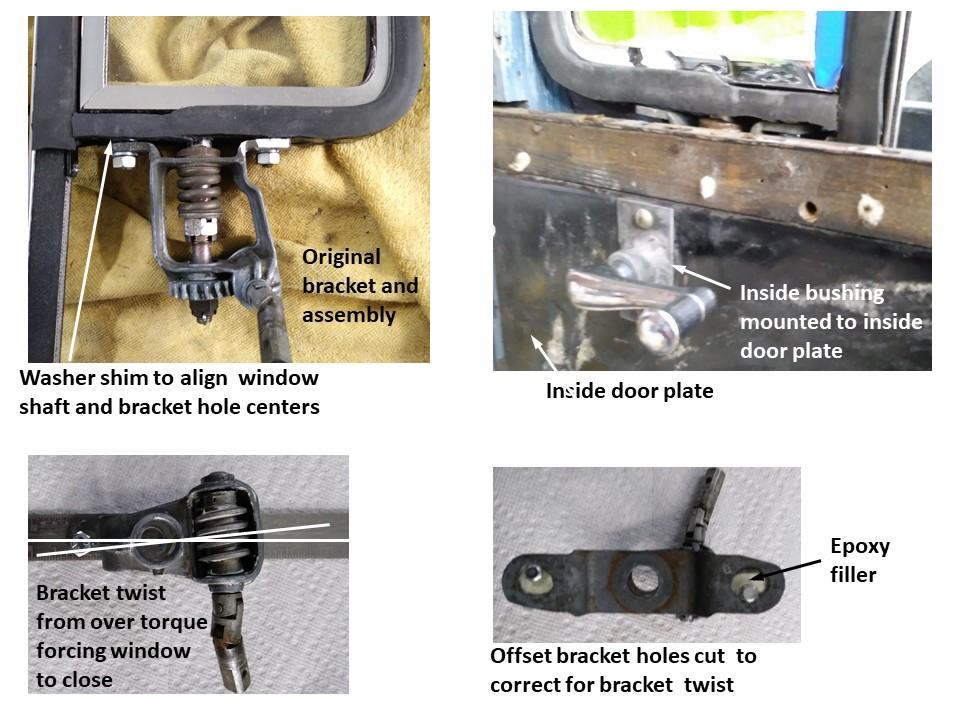

Before getting into the arcane trivia of the vent window issues, the most important takeaway for anyone with ’34-38 vent windows that still crank in and out is: Do not apply a lot of torque on the crank handle to force the window to seat in the weatherstripping. Although inelegant, if it takes much force use your fingers directly on the window frame to get it to close tightly. If, once clear of the weatherstripping, your window opens with a cranking force that alternates between binding and being free as the handle rotates, you probably have a twisted bracket that is set to fail. Treat it as kindly as possible.

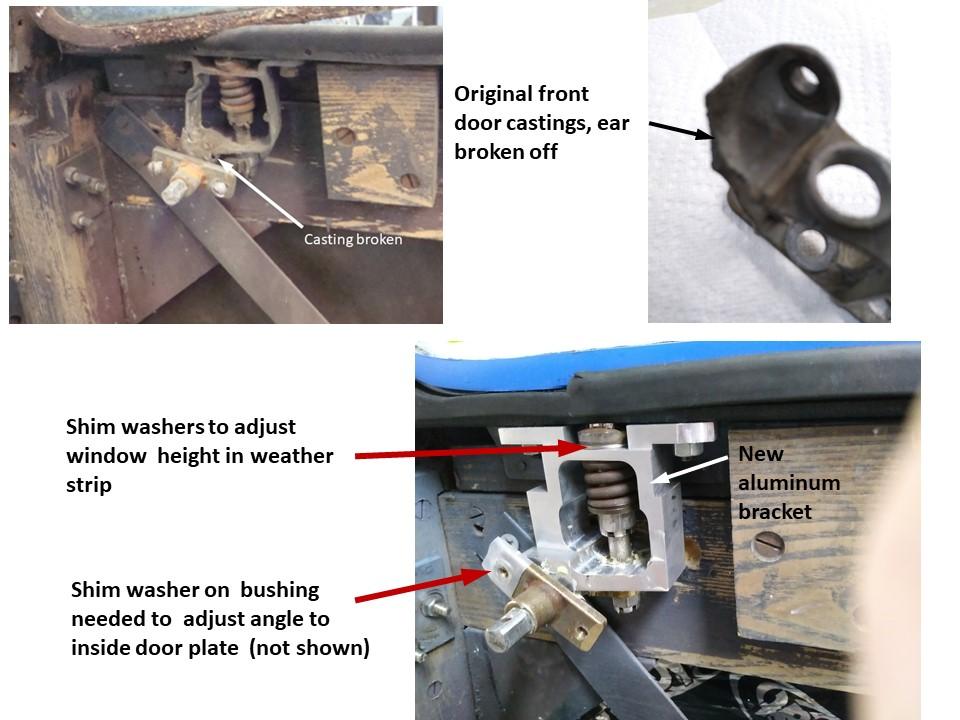

I have 3 bracket castings with broken ears and all castings were twisted out of alignment from excessive torque applied to close vent windows. When I first machined some prototype replacement brackets I thought the twist was intentional, resulting in left hand and right hand opposite parts. That was a couple of years ago and it is only now that I am actually doing the full installations on my club sedan. I am replacing both fronts with new aluminum brackets but the rears (that are installed in the aft part of the door on a club sedan) were still good enough to reuse. The rear assemblies have little universal joints on the worm shaft to deal with some misalignment. The universal joints however are not able to deal with the misalignment from the twisted brackets.

What happens with these mechanisms is that over the years the cranks get over torqued trying to close the vent windows tight in the weatherstrip. Whether the sector gear gets stripped out or not, the cast zinc bracket permanently twists out of alignment. There is a bushing for the crank handle shaft that is screwed into to the large metal door plate that holds the window crank and door latch mechanisms. The bushings result in having three bearings in a line on the crank handle shaft, two in the bracket supporting the worm gear and one mounted to the inside door plate. and when the bracket twists it throws the alignment to the door plate bushing out of whack, resulting in a large force that breaks the bracket casting.

On the rear vent windows with original brackets the twist moves the crank handle shaft aft and a few degrees off of perpendicular, and simply trying to redrill the holes to reposition the bushing to compensate did not work. The shaft must come out perpendicular to the bushing to not bind and put large forces on the bracket. There seemed only two choices to correct, either forcefully twist the bracket back to its original alignment or offset the holes attaching the bracket to the window frame. I understand that some have successfully bent the brackets back, but that seemed pretty risky to me. I filed elongated holes in the brackets which were just enough to realign the bracket on the window frame.

On the front door the new replacement brackets are perpendicular without twist and it seemed there should be no problem aligning with the bronze bushing, but not so. The angle of the inside door plate attaching the bushing was slightly off, and a bind-free installation was only achieved after redrilling new position holes and adding a shim washer on one side of the bushing to get good enough alignment.

Another adjustment to be aware of is the vertical angle of the bracket relative to the window frame shaft needed to center sector gear shaft in the bracket hole. This is not usually an issue but in one case a shim washer had to added between the original bracket and the window frame to get alignment of the sector gear hole.

Also, the vertical position of the window frame in the weatherstrip is important. If there isn’t enough thickness in the washers between the door frame and the bracket it will pull the door frame hard into the bottom of the weather strip and bind the window. The same happens conversely if there is too little thickness, it will jam into the top of the weatherstrip. This adjustment can be thrown off by new chrome plating of the window frame.

Jim, excellent write up, I’ve restored three 34-35 closed cars and they all had this problem. I remember well having to do the offset holes so that the handle shaft would line up inside the wood trim. I wish the new brackets had been available.

This should be published in the service bulletin. Thanks David C.